December 6 is the anniversary of the completion of the Washington Monument. On December 6, 1884, in workers place a nine-inch, 100 ounce, aluminum pyramid inscribed “Laus Deo” (“praise be to God”), on top of the white marble obelisk, completing the monument to the country’s founding father and first president, George Washington.

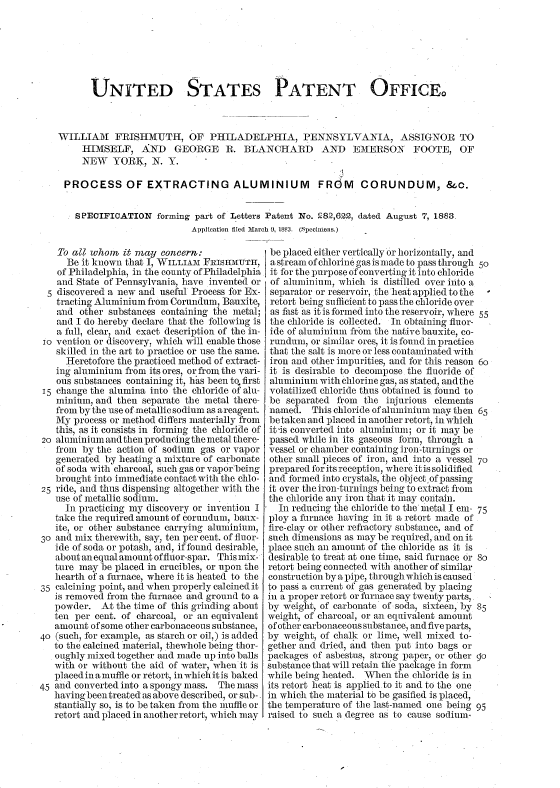

Why aluminum? Because at the time aluminum was considered a precious metal, with a price comparable to silver ($1 per ounce vs, $1.18 per ounce for silver). The process of extracting aluminum was difficult and expensive. An acquaintance of Abraham Lincoln, William Frishmuth, who patented an improvement to the process on August 7, 1883 (U.S. Patent No. 282622) was commissioned to provide the aluminum and cast the pyramid. The completed pyramid was even displayed at Tiffany’s prior to its installation (see above).

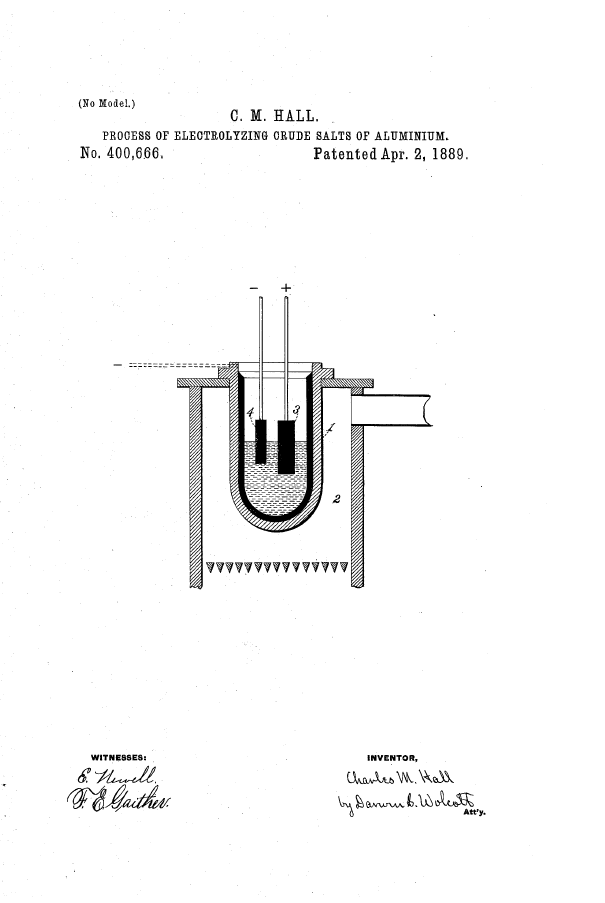

Unfortunately for Frishmuth, On April 2, 1889, Charles Martin Hall patented (U.S. Patent No. 400,666) a much easier and less expensive method for the production of aluminum, which brought the metal into wide commercial use. Hall’s patent interfered with that of Paul Heroult who independently developed the same process at almost the same time. Hall was able to prove priority, and received the patent instead of Heroult.

In 1888 Hall and others founded the Pittsburgh Reduction Company now known as the Aluminum Company of America (ALCOA). By 1914 the cost of aluminum had dropped to 18 cents a pound, and eventually become the stuff of screen doors and soda cans, rather than monuments.

Another inventor Karl Joseph Bayer, an Austrian chemist, developed another process for obtaining aluminum from bauxite about the same time. Hall’s and Bayer’s methods are still used today to produce virtually all of the world’s aluminum.

In a sad post script and reminder that the march of technology can be disruptive, Frishmuth, having lost his monopoly on the production of aluminum, killed himself in his Philadelphia apartment in 1893.